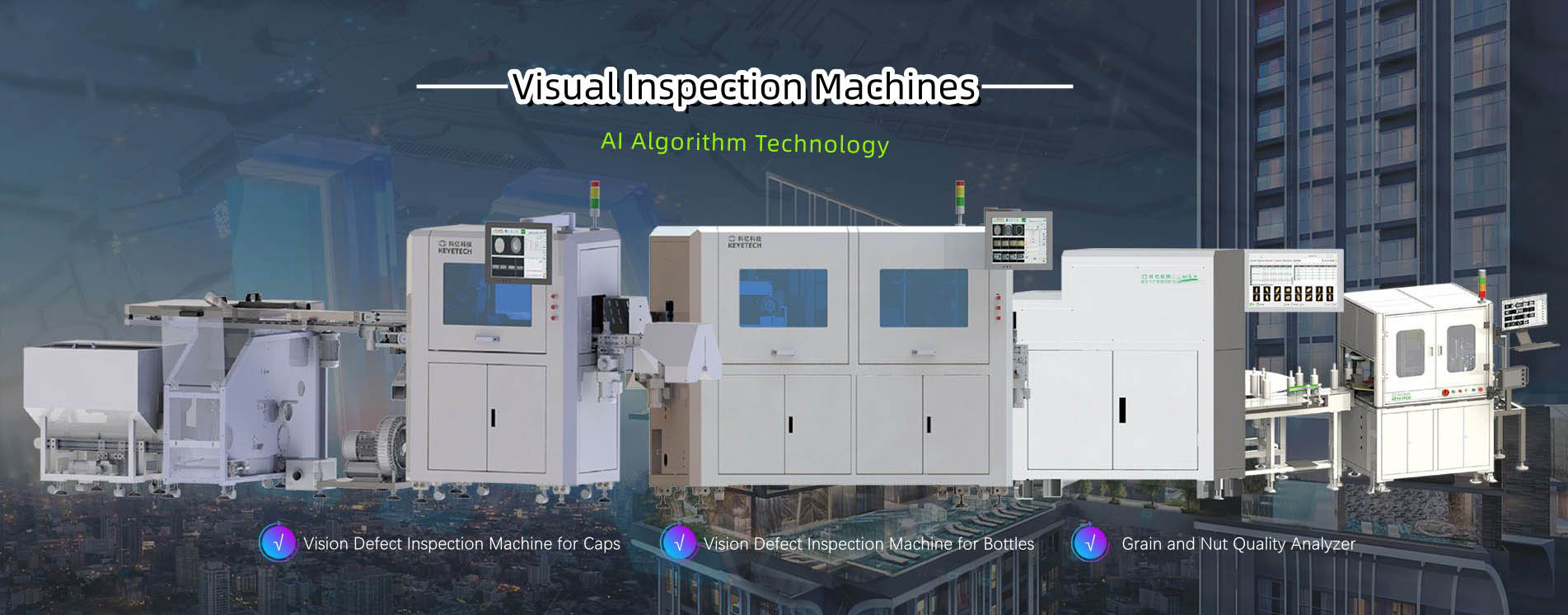

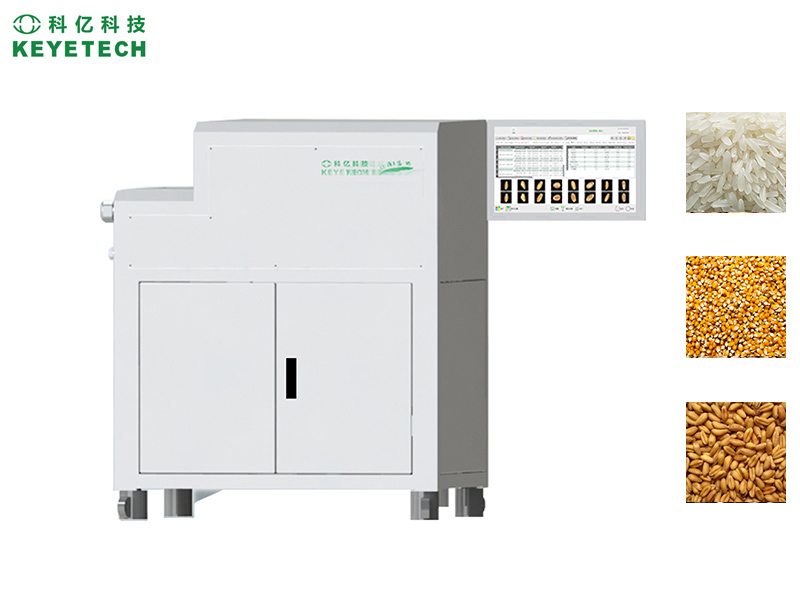

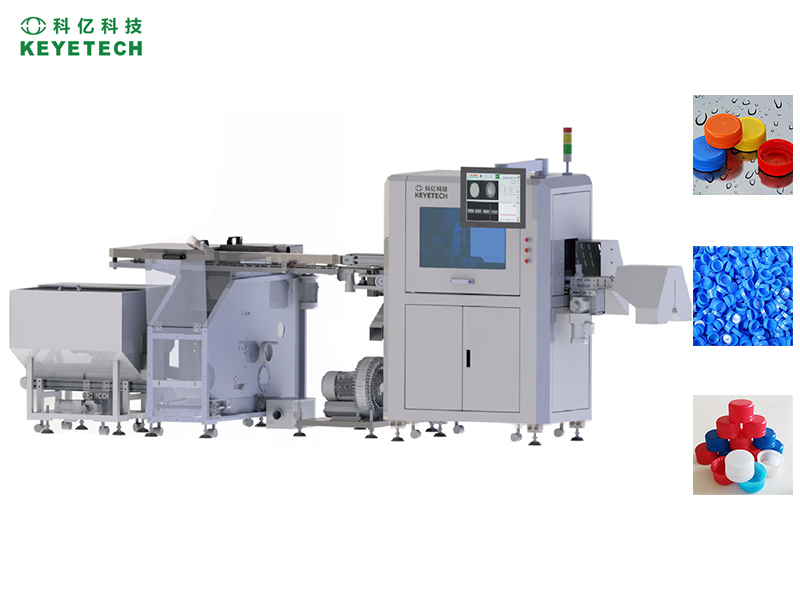

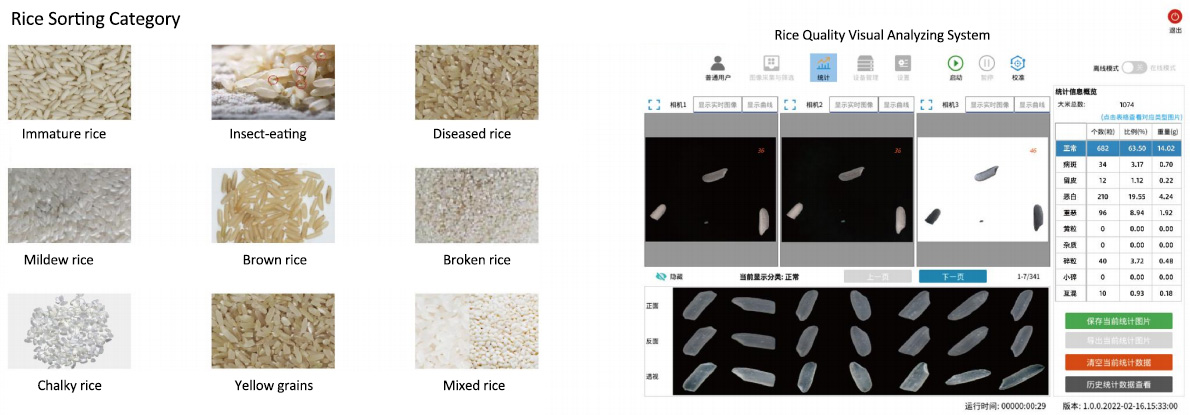

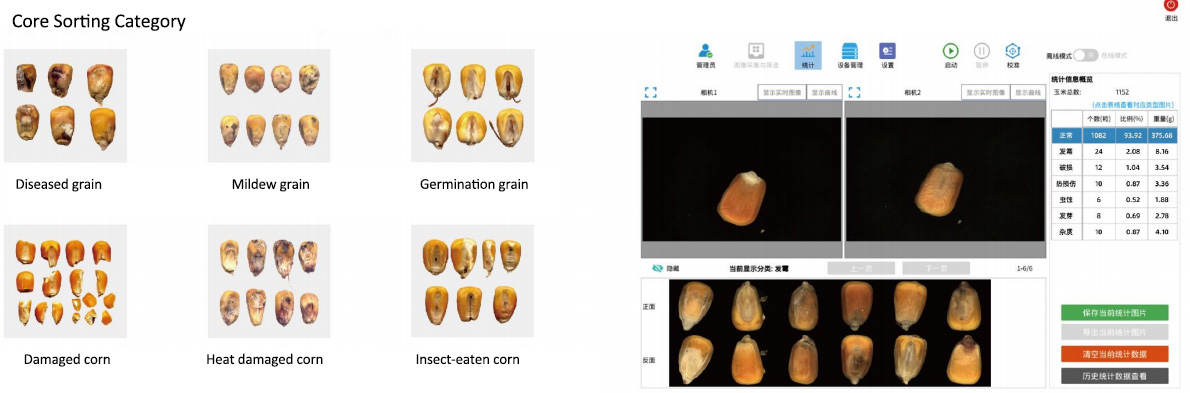

The grain quality analyzer equipment can sort the quality through inspecting the defects like immature, insect-eaten, disease, mildew, broken, germination, etc. It can separate and weigh the grain by the different types according to the international standard.

- AI algorithm precise positioning

- 3 minutes fast analysis

- Easy operation

![]()

Core Technology

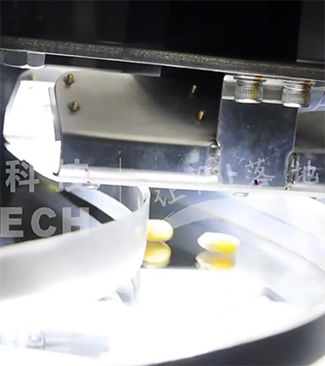

- Automatic binarization: use deep neural network to segment the foreground and background of the image, smoothly segment the grain edge, and accurately locate the grain to be analyzed.

- Adhesion material segmentation algorithm: deep neural network segments the adhering grains to form independent and compete grains, which are analyzed and classified.

- Multi-attribute recognition: this grain quality grading machine adopts lightweight neural and integrates a semi-supervised multi-attribute learning method. The user can label a small number of samples of the grain to be analyzed, and then the data model can be updated to perform fast and high precision analysis of the grain.

![]()

Main Specifications

| Inspection object | Rice | Corn | Wheat |

| Model No. | KVS-GR1 | KVS-GC1 | KVS-GW1 |

| KVS-GR2 | KVS-GC3 | KVS-GW3 | |

| KVS-GR7 | KVS-GC7 | KVS-GW7 | |

| Inspection Speed of Single Outlet | 800~1200pcs/min | 500~800pcs/min | 800~1200pcs/min |

| Voltage | 220V±10% / 50HZ | ||

| Power | 1000~1500W | ||

| Weight | Appr.110Kg | ||

| Ambient Temperature | 10°C ~ 40°C | ||

| Relative Humidity | <85% | ||

Main Configurations

| Description | Model/Brand | Quantity |

| AI Algorithm Software Series | KVIS 16 | 1 Set |

| AI Cloud Service Platform | KeyeTech | 1 Set |

| Industrial Camera | KeyeTech / HIKVISION | 2 Pcs (customizable) |

| Plane Lens | HIKVISION | 2 Pcs (customizable) |

| Strobe Light Source | KeyeTech | 2 Sets |

| Embedded Industrial Controller | Haotent | 1 Set |

| Industrial Power Kit | LRS Seris | 3 Sets |

| Main Control Panel | KY-INS-V21 | 1 Set |

| Vibration Feeder | YQ-130B | 1 Set |

| HID UI System | Haoteng FS | 1 Set |

| Mechanical Structure | 304 Stainless Steel | 1 Set |

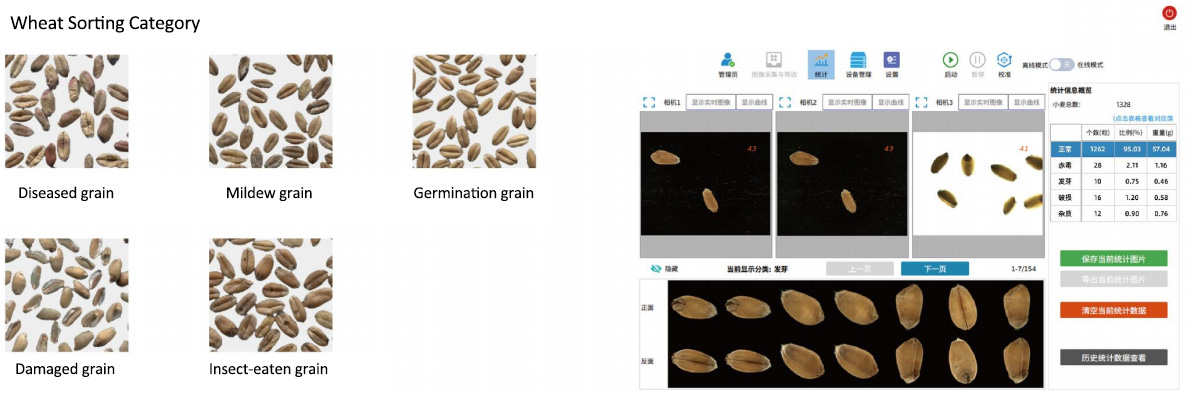

Product Applications

KeyeTech AI grain quality analyzer can be used for quality sorting and defect inspection of grain, like corn, wheat, rice, and it can be also used for inspect melon seed, pine nuts, almond, coffee beans, etc.

Main Technical Advantages

-

HID Industrial CameraSelf-developed high precision industrial camera together with field famous HID lens, equipped with KeyeTech AI algorithm system, it can be achieved to high speed and high precision visual imaging effect.

HID Industrial CameraSelf-developed high precision industrial camera together with field famous HID lens, equipped with KeyeTech AI algorithm system, it can be achieved to high speed and high precision visual imaging effect. -

Customized Light SourcesSelf-developed strobe LED light source, design the special use light source based on different character appearance defects. The integrated cavity light source can get more uniform imaging of the sidewalls.

Customized Light SourcesSelf-developed strobe LED light source, design the special use light source based on different character appearance defects. The integrated cavity light source can get more uniform imaging of the sidewalls. -

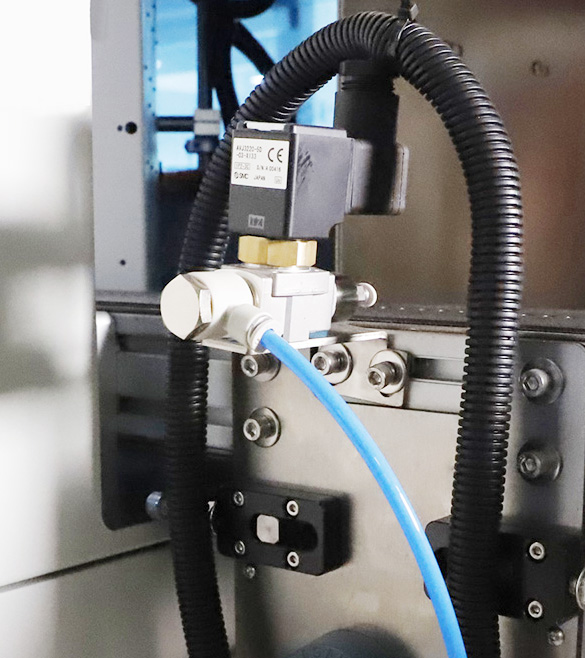

Automatic Control SystemHigh efficiency GPU processing unit and customizable HID human-computer interaction software work together with high performance electromagnetic valve can achieve to full automated control.

Automatic Control SystemHigh efficiency GPU processing unit and customizable HID human-computer interaction software work together with high performance electromagnetic valve can achieve to full automated control. -

KeyeTech AI SystemKeyeTech software system adopt AI deep learning algorithm is the core technical advantages of the machine, reaching to more precise, faster speed imaging and defect recognition, greatly improve the efficiency.

KeyeTech AI SystemKeyeTech software system adopt AI deep learning algorithm is the core technical advantages of the machine, reaching to more precise, faster speed imaging and defect recognition, greatly improve the efficiency.

FAQ

Q: What's kind of products can be inspected?

A: It can main inspect the defects and grade the quality for rice, wheat, corn.

Q: What kind of defects it can inspect?

A: This AI quality analyzer can inspect the defects like damaged, diseased, insect-eaten, mixed, broken, mildew, etc

Q: How many defects can be detected by one machine?

A: The quantity of defects is unlimited, it's depended on customer's detection request.

Q: How many cameras are equipped in the machine?

A: The camera quantity is also decided by the detected defect kinds and positions, the more kinds the more quantity.

Q: What's the definition of the camera?

A: The definition of the camera and lens are depended on your defected precision, i.e, the definition is different if the defected precision is 0.2mm and 0.5mm.

Q: If the camera is self-developed or buy from the professional camera producers?

A: Most of the cameras are designed and developed by ourselves, especially the inspection system is AI algorithm, the camera must match the AI system.

Q: Is the cameras are the most important for the inspection?

A: Camera is one of the most important hardwares of the equipment, the AI algorithm software system is the key technology for the machine.

Q: How to solve installation and adjustment?

A: We will send our skilled engineers to you for installation and adjustment, it takes around one week.

Q: Is difficult to use your machine, how to train our people?

A: Yes, the machine system is sophisticated, but the control for you is easy. We can train your people online via KeyeTech AI platform which is very convenient, and you can also send your technician to our company to learn, it's free.

Q: What's your machine's guarantee? Can you supply the spare parts in the future?

A: We supply the one year warranty for our entire machine, 3 years warranty for hardware like the camera, lens, sensor, (If damaged by personal improper use customer need to purchase from us). We are responsible for the spare parts and maintenance for long time.

BACK