AI Practical Approach | How KeyeTech Achieves AI Applications from 【1 to N】

Sep 04, 2024

This is the best era for AI

Voice recognition, facial recognition unlocking... AI has penetrated every corner of our lives. In recent years, the application of AI is no longer limited to daily life; it has gradually begun to be implemented in the production systems of various industries, such as visual inspection, intelligent sorting, automatic packaging, and more. However, for industry applications, integrating AI into enterprise production models to improve production efficiency is not a smooth process and faces several challenges and difficulties.

In the industrial sector regarding visual inspection: Companies generate massive amounts of data during production processes, but how can they filter out valuable data? How can AI deep learning further enhance control and inspection accuracy? How to acquire and represent industry knowledge, and how to convert it into data that participates in AI calculations and creates value?

These challenges in applying AI to industries require continuous innovation and upgrades to AI platforms to address them.

1.Industry Applications: Huge AI Challenges

In the industrial field, especially in visual inspection, many AI applications face the contradiction of having limited sample data while the accuracy requirements remain high. Various sensors distributed across production equipment generate vast amounts of inspection data daily. However, the final quality of the product is jointly influenced by thousands of parameters such as process parameters, material properties, and production equipment—only a small proportion of the inspection data samples is directly meaningful for quality prediction analysis.

Furthermore, most companies are still relying on manual inspection, with widespread concerns that AI devices may not be as flexible as human inspection.

In the face of these challenges for industry applications, there is a need for a comprehensive and efficient AI machine that meets the demands of various industries for limited samples and high flexibility.

2.KeyeTech: Leading Capability in Industry AI Implementation

KeyeTech has developed AI image visual inspection equipment through years of continuous innovation and upgrades, enabling machines to possess collaborative and cognitive abilities similar to those of humans. Its AI platform can simulate massive data with a small number of samples, labeling and analyzing samples to build inspection models. It is also equipped with advantages such as high efficiency, stability, and the ability to switch between multiple models, solving issues related to the accuracy, efficiency, safety, and costs associated with manual inspection.

01 Quality Guardian

In light of the limited sample data faced by enterprises, KeyeTech’s AI platform, based on deep learning, has data augmentation capabilities that allow a small number of samples to simulate massive data, thereby constructing its own AI database. When the equipment is in operation and detects a defective product, it quickly eliminates defect, ensuring that the products leaving the factory are defect-free.

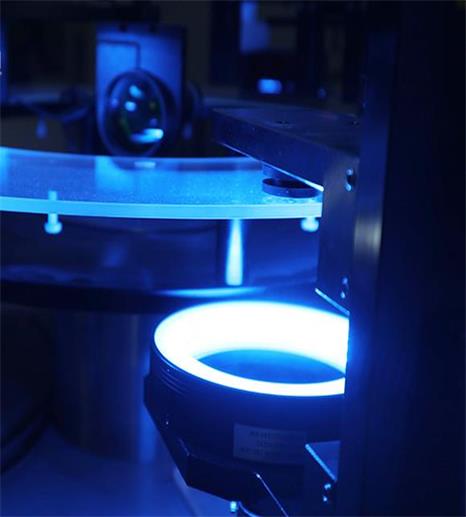

02 Professional Image Inspector

Customized LED light sources and industrial cameras are equipped with an intelligent processing platform. When the products to be tested enter the inspection area, the industrial camera can capture multiple photos in about 0.1 seconds. Through AI algorithms, it compares against the sample database, simulating human thought processes to conduct quality inspections on product appearances. Issues such as black edge, material deficiency, and deformation of bottles are quickly recognized and eliminated.

03 Safety Guardian

Currently, KeyeTech's AI visual inspection machine is applied in industries such as packaging, food, 3C (computer, communication, consumer electronics), and medical fields. By leveraging AI for quality inspection and classification, it can reduce the number of inspection personnel by two-thirds.