Search

Appearance Defect Detection of Bottle Body

The appearance defect inspection of the bottle body is a common problem in daily production. For manufacturers in industries such as pharmaceuticals, dairy products, alcoholic beverages, seasonings, and daily chemical products, due to the increasing demand for product packaging refinement, quality, and continuous batch production, the market has put forward higher standards for bottle factory quality testing. The emergence of machine vision inspection machines based on AI algorithms, it has become a new tool to assist enterprises in efficient production.

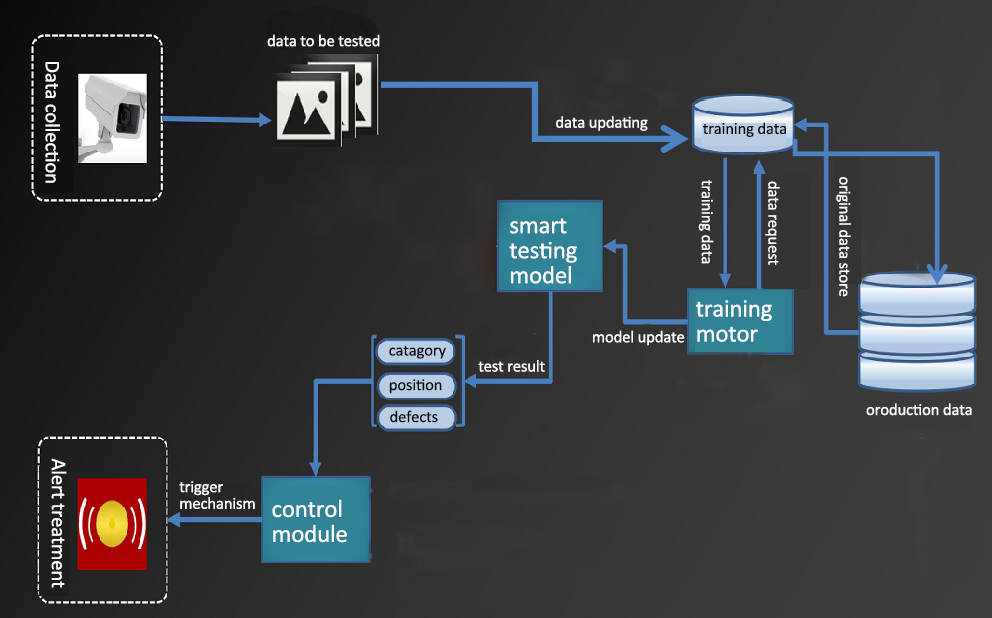

Vision Defect Inspection Solution of Bottle Body

Based on the theory of computer vision and pattern recognition, and equipped with the AI edge computing unit developed by KeyeTech, it fully meets the computing power support under the requirements of high-definition and high-speed. It has the advantages of high computing power, high stability, and low power consumption, and optimizes the problem of computing power distribution in multi camera collaborative processing.

Software & Hardware Platform

(1) Self developed high-precision CCD/CMOS industrial camera (camera+lens)

(2) Self developed surface light sources, circular light sources, and other LED light sources

(3) Semi supervised learning mode

(4) Self developed AI edge computing unit, a high-performance embedded computing platform for industrial scenarios

(5) Building an AI cloud training platform independently

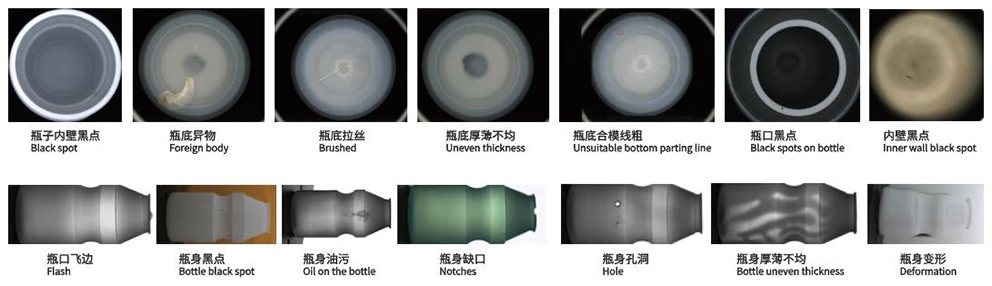

Detection Contents

Bottle defects: black spots, color difference, impurities, threads, lifting rings, notches, residues, burrs, bubbles, holes, uneven thickness, deformation, size, spray code, trademark, mold number, etc

Bottle material: PET, PE, PP, HDPE, PC, etc

Widely Applications

KeyeTech AI visual defect inspection technology is widely used in industries such as pharmaceuticals, dairy products, seasonings, alcoholic beverages, and daily chemicals.

Solution Advantages

High efficiency

Self developed AI edge computing unit has faster speed, lower power consumption, stronger continuous computing capability, no power failure at high temperature, and stable operation.

High Integration

Integrating light, machinery, electronics, computing, and software, we have built an AI platform with higher integration, faster computation, and stronger processing capabilities.

Strong data compatibility

The semi supervised learning mode effectively solves the problem of small data samples and difficult labeling.

High flexibility

Support fast switching of detection scenarios

Easy to operate

3 minutes to get started, with 7X24 hours of remote operation and maintenance support.