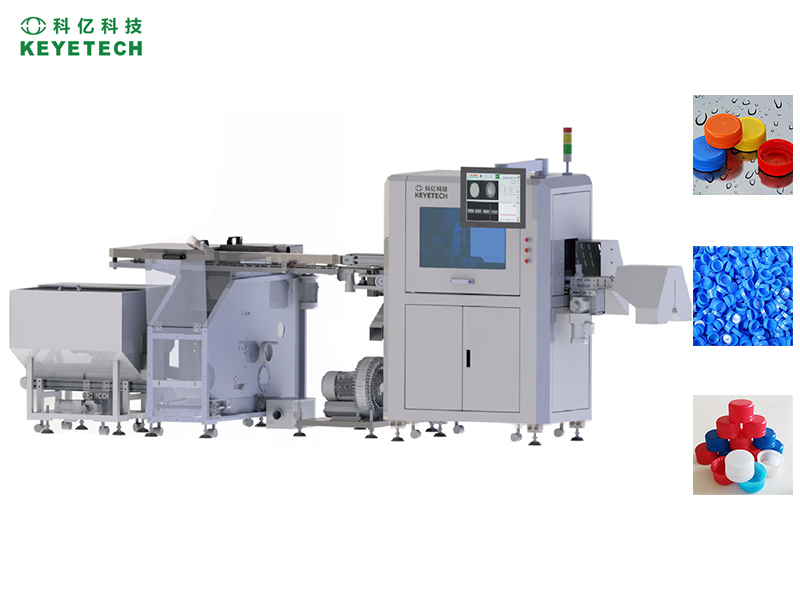

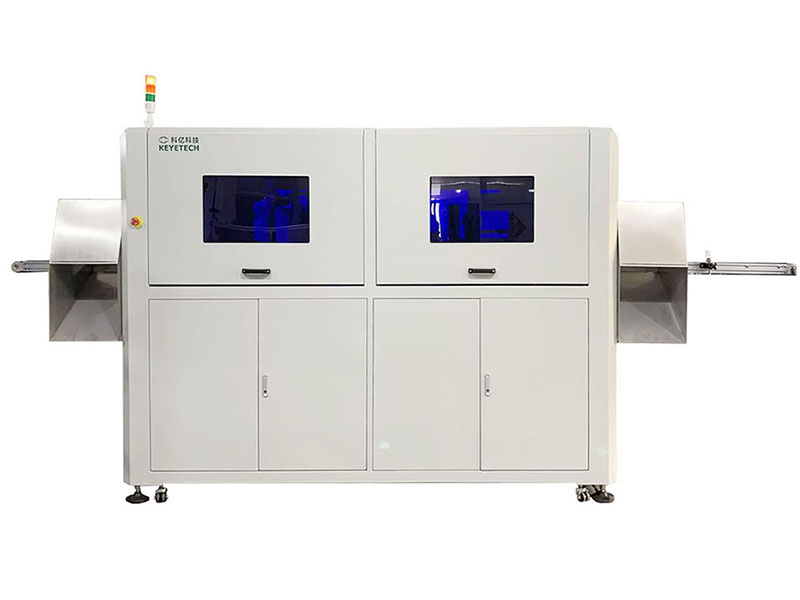

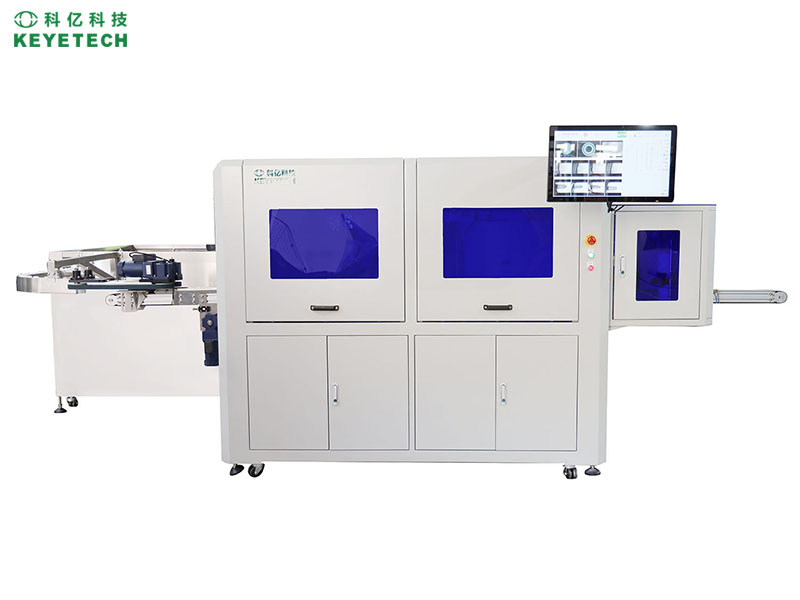

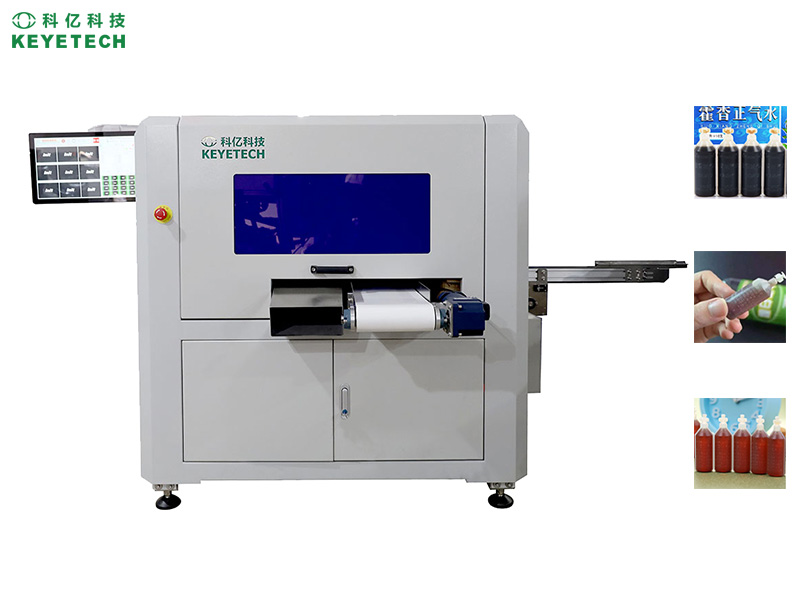

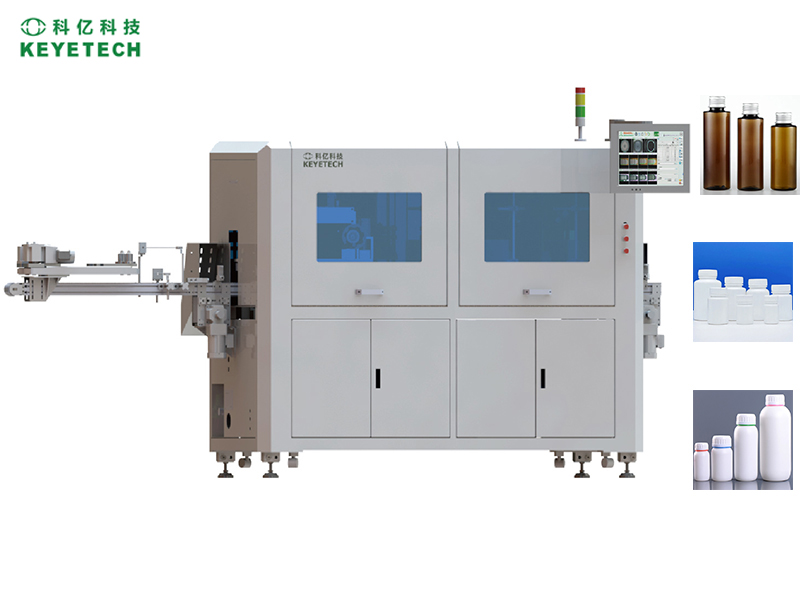

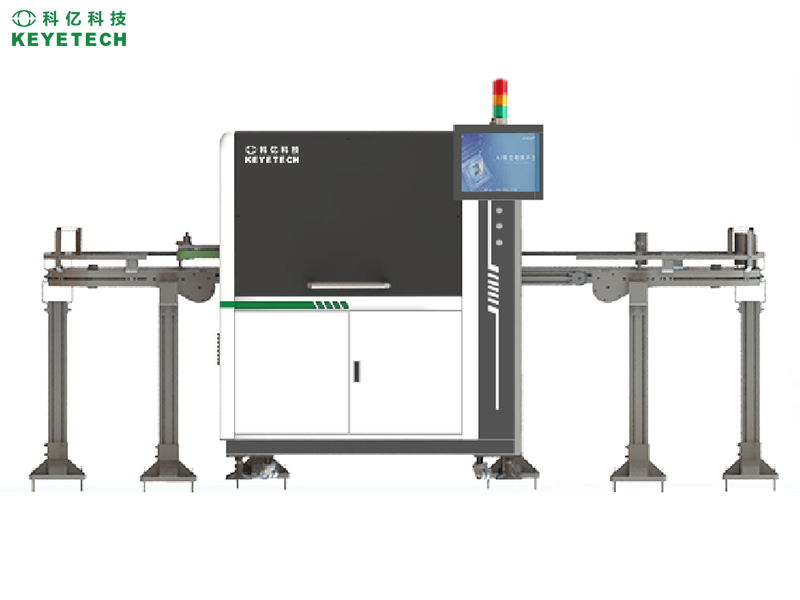

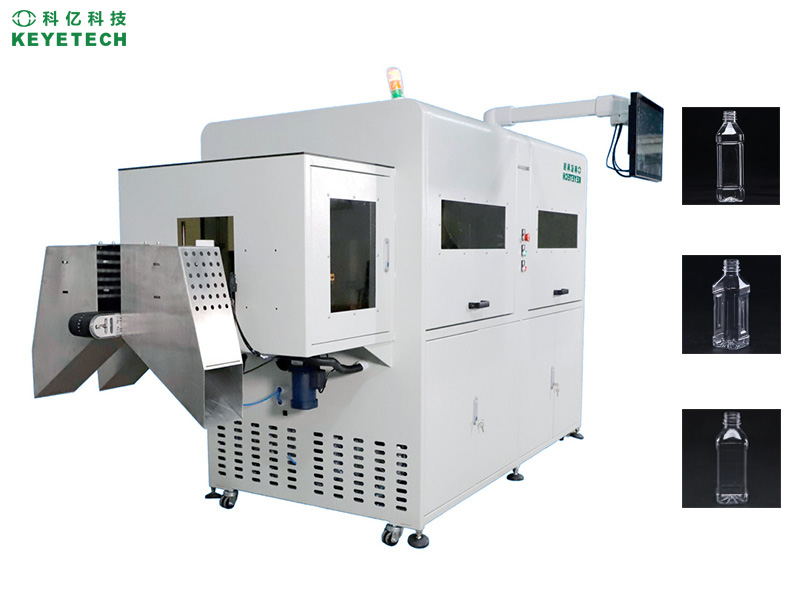

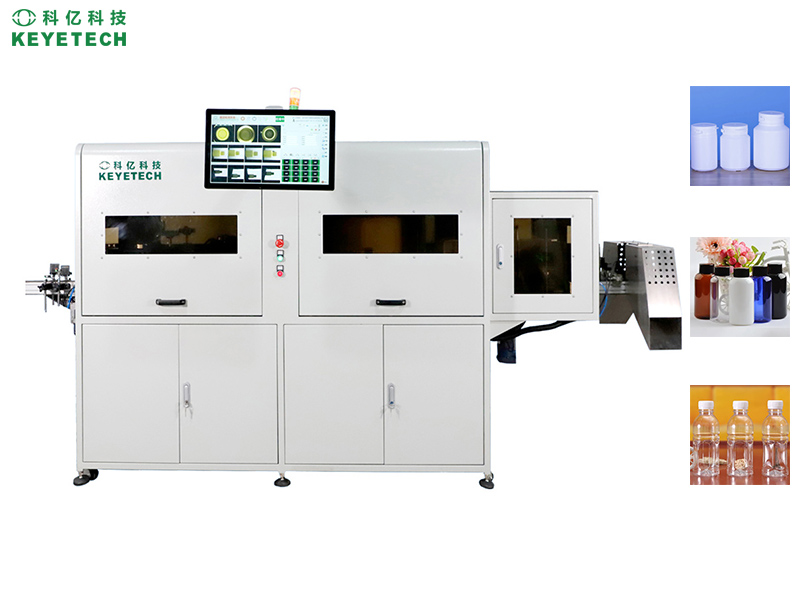

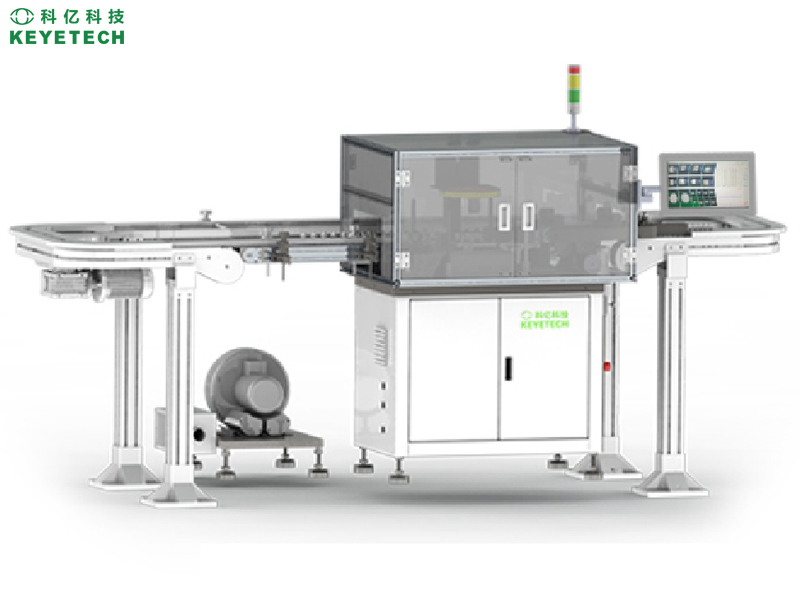

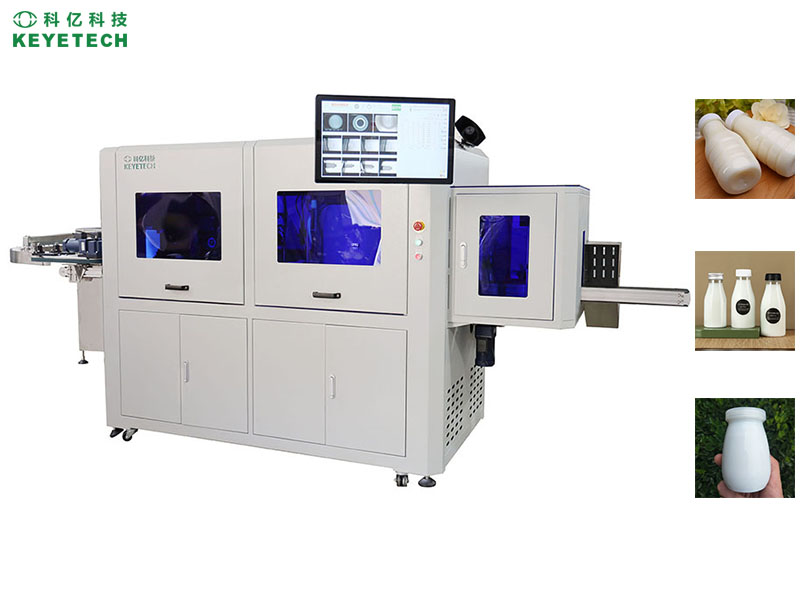

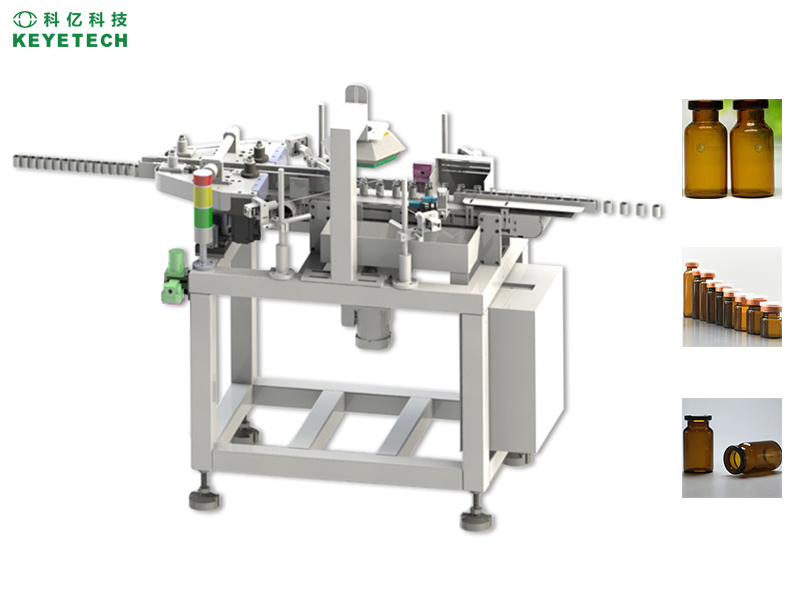

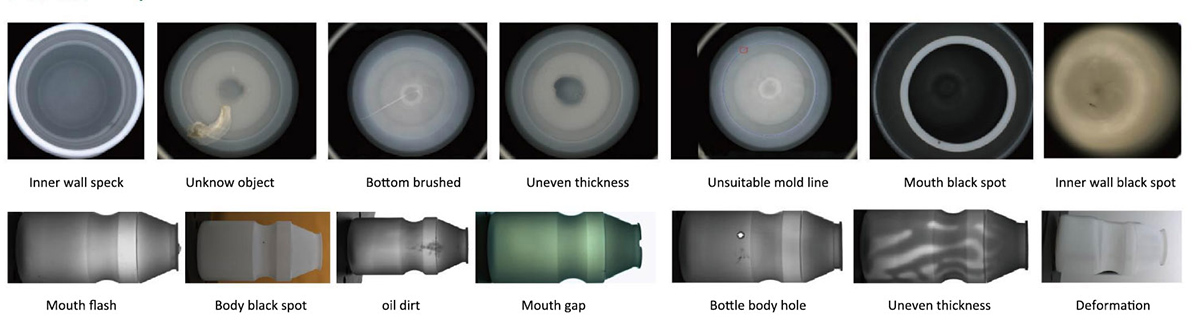

The plastic bottle and container visual inspection machine is an AI detection system independently developed by the KeyeTech, the machine is customized to inspect the appearance defect of plastic bottles and containers, transparent and opaque ones. It equipped a HD industrial camera to high-definition identify inspection on PET/PE bottles and containers. After processing by an optical image processing system, it can recognize and remove various defects on the detection bottle body online. This visual inspection system has powerful GPU chip computing power and the latest AI algorithm system, which can inspect various defects on the bottle body and bottle mouth, such as black spots, burrs, impurity, deformations, etc, this vision inspection equipment can be used for water and beverage bottles, pharma bottles, daily chemical product bottles visual inspection.

![]()

Main Features

- AI cloud platform for high-precision and real-time operation, remote operation support.

- Edged computing technology and high capacity computing unit.

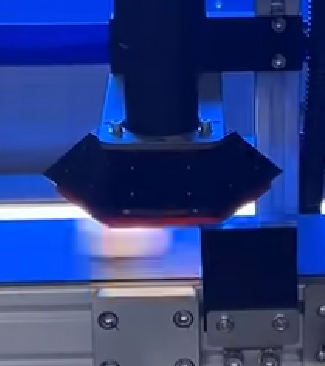

- Self-developed optic imaging system with interrelationship analysis design between lighting and imaging.

- Entire technology chain in optical, electricity, algorithm, mechanic and software

![]()

Main Specifications

| Defect Types |

Black spot,impurity, stain, thread, burr, cracks, flashing, deformation ... |

| Inspection Positions | Bottle mouth, bottle bottom, bottle body, sidewalls. |

| Inspect Speed | 150pcs~300pcs/min (customizable) |

| Precision | +/- 0.1mm |

| Accuracy Rate | 99.9% |

| Compressed Air | 0.5Mpa~0.8Mpa |

| Net Weight | About 350Kg |

| Dimension | 3550*1030*1800mm |

| Power | 5~7Kw |

Main Configurations

| Description | Model/Brand | Quantity |

| AI Algorithm Software Series | KVIS V16.0 | 1 Set |

| AI Cloud Service Platform | KeyeTech | 1 Set |

| Industrial Camera | KeyeTech / HIKVISION | 6~18 Pcs (customizable) |

| Plane Lens | HIKVISION | 6 ~18Pcs (customizable) |

| Strobe Light Source | KeyeTech | 1 Set |

| Photoelectric Sensor | SICK (Germany) | 1 Pc (customizable) |

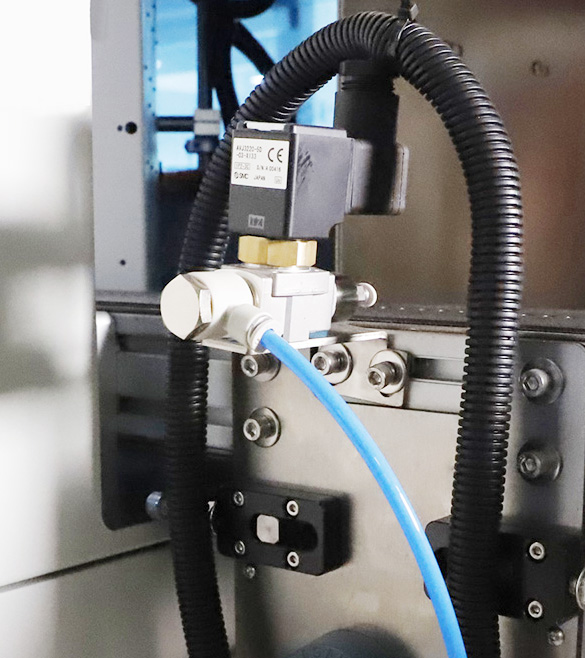

| Electromagnetic Valve | SMC (Japan) | 1 Pc (customizable) |

| Industrial Power Kit | LRS Seris | 3 Set |

| Main Control Panel | KY-INS-V21 | 1 Set |

| Embedded Computing Unit | KYEBS-1684 | 1 Set (Optional) |

| Touch Screen interface | 21 Inch | 1 Set |

| Mechanical Structure | Stainless Steel/Carbon steel | 1 Set |

Product Applications

Detect Type for Example:

Main Technical Advantages

-

HID Industrial CameraSelf-developed high precision industrial camera together with field famous HID lens, equipped with KeyeTech AI algorithm system, it can be achieved to high speed and high precision visual imaging effect.

HID Industrial CameraSelf-developed high precision industrial camera together with field famous HID lens, equipped with KeyeTech AI algorithm system, it can be achieved to high speed and high precision visual imaging effect. -

Customized Light SourcesSelf-developed strobe LED light source, design the special use light source based on different character appearance defects. The integrated cavity light source can get more uniform imaging of the sidewalls.

Customized Light SourcesSelf-developed strobe LED light source, design the special use light source based on different character appearance defects. The integrated cavity light source can get more uniform imaging of the sidewalls. -

Automatic Control SystemHigh efficiency GPU processing unit and customizable HID human-computer interaction software work together with high performance electromagnetic valve can achieve to full automated control.

Automatic Control SystemHigh efficiency GPU processing unit and customizable HID human-computer interaction software work together with high performance electromagnetic valve can achieve to full automated control. -

KeyeTech AI SystemKeyeTech software system adopt AI deep learning algorithm is the core technical advantages of the machine, reaching to more precise, faster speed imaging and defect recognition, greatly improve the efficiency.

KeyeTech AI SystemKeyeTech software system adopt AI deep learning algorithm is the core technical advantages of the machine, reaching to more precise, faster speed imaging and defect recognition, greatly improve the efficiency.

FAQ

Q: What's kind of bottles can be inspected?

A: It can inspect the all kinds of plastic bottles and containers.

Q: What kind of defects it can inspect?

A: All the defects that can be seen by eyes is able to be inspected, it is appearance defect inspection.

Q: How many defects can be detected by one machine?

A: The quantity of defects is unlimited, it's depended on customer's inspection request.

Q: How many cameras are equipped in the machine?

A: Our standard one is equipped 6 cameras, the exact camera quantity is also decided by the detected defect kinds and positions.

Q: What's the definition of the camera?

A: The definition of the camera and lens are depended on your defected precision, i.e, the definition is different if the defected precision is 0.1mm and 0.5mm.

Q: If the camera is self-developed or buy from the professional camera producers?

A: Most of the cameras are designed and developed by ourselves, especially the inspection system is AI algorithm, the camera must match the AI system.

Q: Is the cameras are the most important for the inspection?

A: Camera is one of the most important hardwares of the equipment, the AI algorithm software system is the key technology for the machine.

Q: How to solve installation and adjustment?

A: We will send our skilled engineers to you for installation and adjustment, it takes around one week.

Q: Is difficult to use your machine, how to train our people?

A: Yes, the machine system is sophisticated, but the control for you is easy. We can train your people online via KeyeTech AI platform which is very convenient, and you can also send your technician to our company to learn, it's free.

Q: What's your machine's guarantee? Can you supply the spare parts in the future?

A: We supply the one year warranty for our entire machine, 3 years warranty for hardware like the camera, lens, sensor, (If damaged by personal improper use customer need to purchase from us). We are responsible for the spare parts and maintenance for long time.

Q: What's detailed information i need to supply to get a quote?

A: Customers need to supply some exact answers to us for a quote:

- How many different plastic bottles in total to be inspected?

- What's color and size of the plastic bottles and containers? (need samples or drawing)

- How many different defects need to be inspected?(need samples or drawing)

- Inspect for target position or 360° full positions?

- What's the request of the inspection speed?

- Any special requirement for inspection precision?

- Inline or offline inspection? If online how to match your cap machine, if offline need cap handling device from us or not?

The above are part of the questions we need to discuss before the quote, for a exact quote we also need physical defect samples.

Remarks: In order to design equipment that meets customer needs more accurately, we need to have detailed communication between both parties on the details of testing, and only then can we confirm the equipment parameters. This requires some time and process, and we hope that customers with purchasing needs can come to our company for face-to-face communication and inspection.