Search

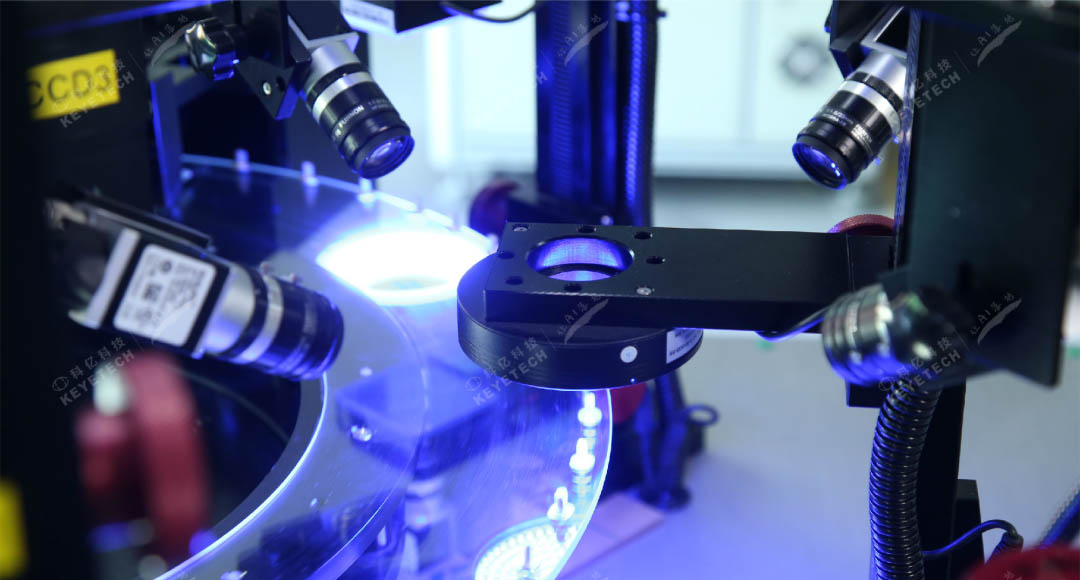

With the rapid implementation of artificial intelligence technology and the continuous development of the intelligent robot industry, visual inspection machines are unleashing even stronger vitality. The typical structure of visual inspection equipment design mainly consists of five parts, namely: lighting, lens, camera, image acquisition, and computing hardware units.

What is the visual inspection?

Visual inspection system refers to the use of machine vision products (i.e. image capture devices, divided into CMOS and CCD) to convert the captured target into an image signal, which is transmitted to a dedicated image processing system and converted into a digital signal based on pixel distribution, brightness, color, and other information; The image system performs various operations on these signals to extract features of the target, and then controls the on-site equipment actions based on the discrimination results.

Customization process of visual system

1. Software Testing

The cyclic process of ensuring the correctness of software processes and the correct application logic relationships, discovering vulnerabilities in the system, conducting research and development modifications, and testing verification.

2. Hardware testing

Conduct hardware reliability testing on the hardware itself (aging testing, compatibility testing, failure rate testing) and the environment to determine whether the software can run in multiple hardware configuration environments.

3. Joint debugging test

Test the software and hardware joint debugging function to verify the correctness of electrical and software signal communication logic, light source, camera and other hardware triggering functions such as photography and scanning, as well as the statistics of detection results.

4. Model testing

Focus on the functional testing, performance testing, evaluation of model indicators, and analysis of indicator results of the model.

How to carry out testing of visual inspection system?

Application type: Accurately and detailedly understand the changes in product testing standards, external dimensions, and other factors that affect testing, and preliminarily evaluate whether they can meet the requirements.

Stage requirements: Customers' demands for visual inspection efficiency, quantifying the time required for visual inspection steps.

Accuracy requirement: Control the accuracy of product defect detection.

Installation space: Confirm if there are any restrictions on the installation of visual equipment in the on-site environment.

Requirement analysis: Organize key customer requirements and analyze their feasibility.

Hardware design: Selection of visual system platform, camera, lens, and light source.

Software design: Use third-party visual software or develop visual processing software independently.

Feasibility verification: Set up software and hardware environments, customize human-computer interaction interfaces, and conduct preliminary testing to determine if they can meet customer needs.

Cloud platform development: Collect product defect sample images, upload and store images, select images, annotate, upload, train, test, optimize, and apply.