What problems can the layout of Keye visual inspection industry solve

May 21, 2024

High precision AI algorithm, meeting hundreds of subdivision scenarios

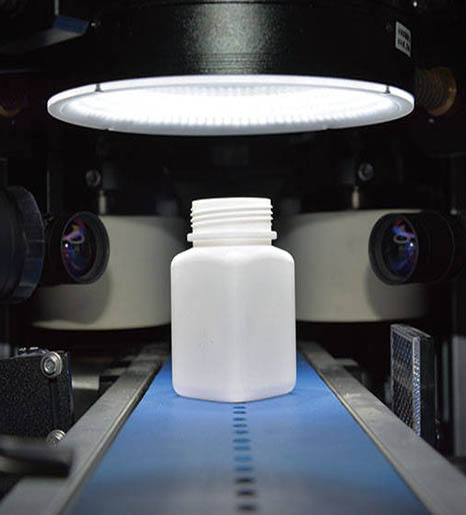

Product appearance defect Inspection

Mainly used for product appearance defect visual inspection system in the industrial field, including black spots, scratches, damages, foreign objects, discoloration, deformation, specifications, third phase, EAN product barcodes, etc

Application scope

Machine vision inspection for bottle cap bottle body, bottle preform, cup packaging, filling, spray coding (missing, blurry, not spray coded), alcohol packaging, bowl, pharmaceutical packaging; Non woven fabric, earth cloth, denim fabric, embroidered fabric; Capacitors, lighting displays, electronic components, shielding covers, connectors; COVID-19 self test kit, gloves, measuring cup, syringe, pregnancy test stick, etc.

Grain quality analysis

Automated, information-based, and intelligent solutions for incomplete grain analysis

The KVS-G series grain quality sorting machine consists of a visual system, software system, and other module structures. When the grain enters the camera's field of view, it is photographed and the characteristics of a complete grain are comprehensively obtained through registration algorithms. Artificial intelligence algorithms are used for attribute recognition to determine whether there are problems such as disease spots, mold, sprouting, damage, and insect erosion.

Application scope

Quality analysis of stable agricultural products such as rice, corn, wheat, melon seeds, pine nuts, almond wood, coffee beans, etc., classified and counted according to national standards, separated and weighed (optional) for different types.

Resource recycling

Based on AI algorithm classification, template matching algorithm, data preprocessing algorithm and other technologies, Keye Technology can accurately identify the materials that customers need to classify from mixed, stacked, adhesive, damaged, and dense materials, and sort them accurately.

Application scope

Classification of construction waste, kitchen waste, industrial waste, recycled plastics, household waste, etc.